Constant Systems

Cell Disruption Made Easy

High Pressure

99% Sample processing

FIND OUT MORE

Scalability

FIND OUT MORE

Versatility

Wide range of organisms samples

FIND OUT MORE

Client Support

Enhancing the reliability of your research

FIND OUT MORE

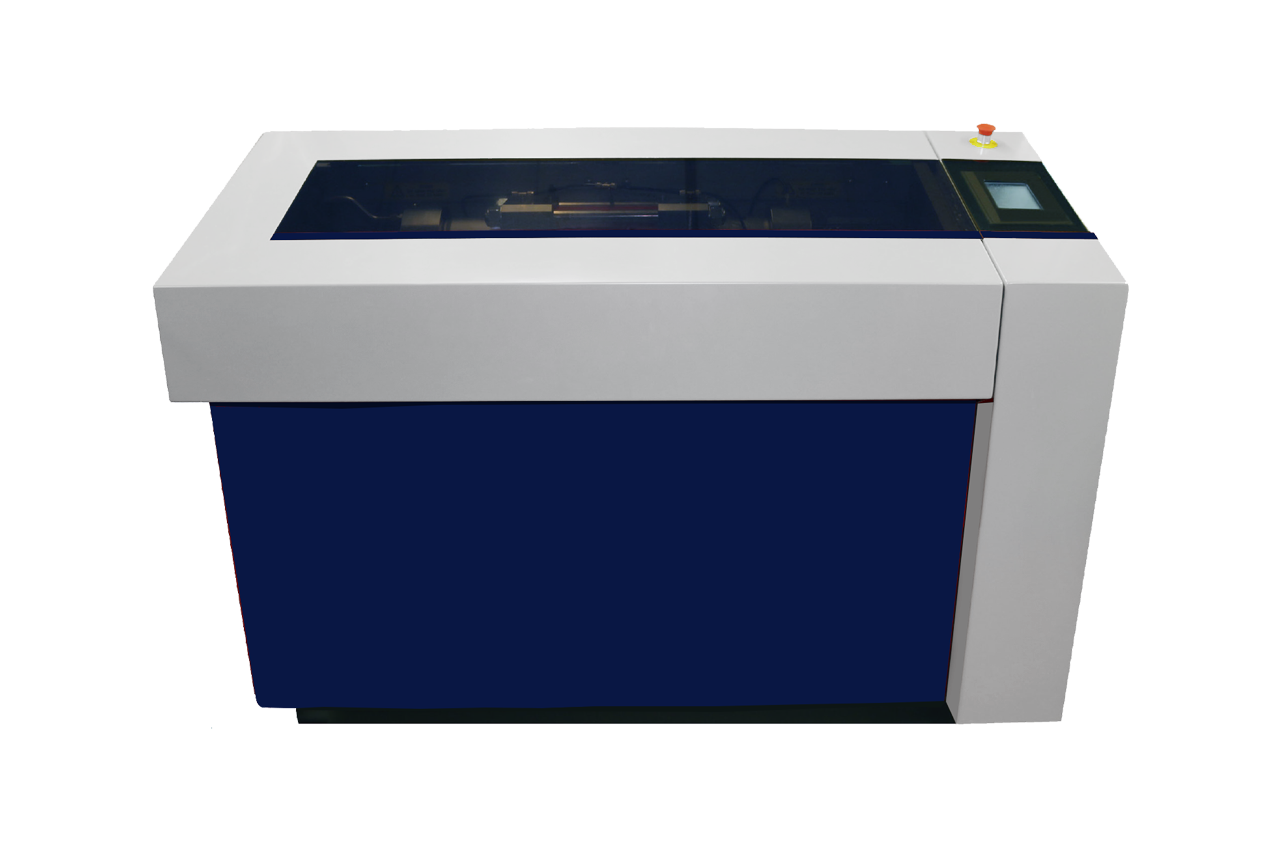

Cell Disruption

Constant Systems Advanced Technology Overcomes Cell Disruption Issues

Cell disruption is a critical step in biotechnological research, impacting the efficiency of downstream processes.

Why Constant Systems are leagues ahead of the compition:

Constant Systems

Pioneering innovative solutions in cell disruption

For over 35 years, Constant Systems has pioneered innovative solutions in cell disruption, setting industry standards with our high-pressure technology. Constant Systems’ equipment is renowned for its unique hydraulic design and precise control systems, ensuring efficient and reproducible cell lysis. Our product range, including the One Shot, Multi Cycle, Continuous Flow, and High Flow Rate Cell Disruptors, caters to diverse research needs, from small-scale samples to large-scale processes.

IBioIC26 – BioSolutions for Tomorrow’s World – 12th Annual Conference in partnership with BBIA

IBioIC26 – BioSolutions for Tomorrow’s World – 12th Annual Conference in partnership with BBIA

The Microbiology Society Annual Conference 2026

The Microbiology Society Annual Conference 2026